模板组合

High Automation: Minimizes manual intervention, improving efficiency.

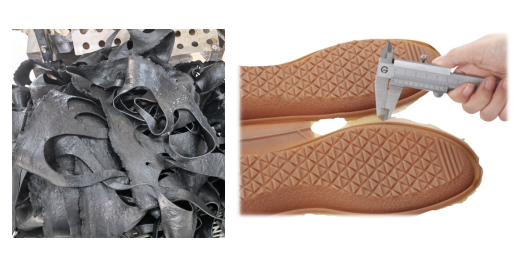

Material Savings: Directly processes strip-shaped rubber from open milling, reducing waste from edge trimming in traditional processes.

Time Efficiency: Enables continuous production cycles, reducing overall production time.

Complex Shape Molding: Supports hollow molding, minimizing trimming steps and simplifying post-processing.

Prevents Color Bleeding: Ensures better product appearance and consistency.

Streamlined Process: Simplifies manufacturing steps for greater efficiency.

Reduced Mold Wear: High production efficiency lowers the need for additional molds, cutting costs.

Improved Product Quality: Reduces defect rates and enhances overall product consistency.

Energy Efficiency: Optimized design reduces power consumption.

| NO. | ITEM | PARAMETERS | |

| 1 | No. of working stations工作站 | 2 | |

| 2 | Clamping force(KN)锁模力 | 1650 | |

3 | Clamping Stroke(mm)合模行程 | 300 | |

4 | Space between heating plate(mm)加热板空间范围 | 230~480 | |

5 | Heating Plate Size(L×W mm)加热板尺寸 | 460×340 | |

6 | Power of heating plate(KW)加热板功率 | 12×2 | |

7 | Mould size(L×W mm)模具尺寸 | (400~460) ×(300~360) | |

8 | Mould thickness(mm)模具厚度 | 80~440 | |

9 | Screw Diameter(mm)螺杆直径 | 45 | |

| 10 | Injection barrel diameter(mm)注射筒直径 | 65 | |

11 | Injection pressure(MPa)最大注射压力 | 210 | |

12 | Injection volume(ml)最大注射量 | 850 | |

13 | The injection stroke(mm)注射冲程 | 320 | |

14 | Heating power of Mold Temperature Controllers(KW)模温机的加热功率 | 5.5×2 | |

15 | Oil tank capacity of Mold Temperature Controllers(L)模温机的油箱温度 | 48 (12×4) | |

16 | Max. feeding rubber strip width(mm)喂料胶条宽度 | 45 | |

17 | Max. feeding rubber strip thickness(mm)喂料胶条厚度 | 8 | |

18 | System pressure(MPa)系统压力 | 21 | |

19 | Motor power of oil pump(KW)油泵电机功率(千瓦) | 16 | |

20 | Oil tank capacity(L)油箱容量 | 400 | |

21 | Total power(KW)总功率 | 55 | |

22 | Machine dimensions(L×W×H mm)机器尺寸 | 3680×2020×(2750~3250) | |

23 | Machine weight(KG)机器重量 | 9500 | |

- Tel

- *Title

- *Content

- Name:

- Amy Ren

- Tel:

0086-13958255267

0086-574-88033926

- Email:

- amy@larytec.com

- Skype:

- Skype:amyren600

- Address:

- No.9, JinGu Middle Road,Yinzhou District, Ningbo City, China

E-mail:inlary@larytec.com

E-mail:inlary@larytec.com