Home / All / Rubber shoe sole injection machine / Single color rubber injection for shoe sole /

CS Rubber Shoe Soles Making Machine

CS Rubber Shoe Soles Making Machine

Detail Information

Rubber shoe soles making machine

The rubber sole injection molding machine from LARY is suitable for producing various rubber products, including shoe soles, seals, and rubber tubes.

Through its unique molding process, LARY enables the efficient production of complex-shaped rubber products, enhancing both product quality and production efficiency.

ADVANTAGES

Key Advantages Await Your Discovery

for LARY LRS165 Rubber Shoe Sole Injection Molding Machine

- 1. High Automation: Minimizes manual intervention, improving efficiency.

- 2. Material Savings: Directly processes strip-shaped rubber from open milling, reducing waste from edge trimming in traditional processes.

- 3. Complex Shape Molding: Supports hollow molding, minimizing trimming steps and simplifying post-processing.

- 4. Time Efficiency: Enables continuous production cycles, reducing overall production time.

- 5. Prevents Color Bleeding: Ensures better product appearance and consistency.

- 6. Streamlined Process: Simplifies manufacturing steps for greater efficiency.

- 7. Reduced Mold Wear: High production efficiency lowers the need for additional molds, cutting costs.

- 8. Improved Product Quality: Reduces defect rates and enhances overall product consistency.

- 9. Energy Efficiency: Optimized design reduces power consumption.

PARAMETERS

| NO. | ITEM | PARAMETERS | |

| 1 | No. of working stations | 2 | |

| 2 | Clamping force(KN) | 1650 | |

3 | Clamping Stroke(mm) | 300 | |

4 | Space between heating plate(mm) | 230~480 | |

5 | Heating Plate Size(L×W mm) | 460×340 | |

6 | Power of heating plate(KW) | 12×2 | |

7 | Mould size(L×W mm) | (400~460) ×(300~360) | |

8 | Mould thickness(mm) | 80~440 | |

9 | Screw Diameter(mm) | 45 | |

| 10 | Injection barrel diameter(mm) | 65 | |

11 | Injection pressure(MPa) | 210 | |

12 | Injection volume(ml) | 850 | |

13 | The injection stroke(mm) | 320 | |

14 | Heating power of Mold Temperature Controllers(KW) | 5.5×2 | |

15 | Oil tank capacity of Mold Temperature Controllers(L) | 48 (12×4) | |

16 | Max. feeding rubber strip width(mm) | 45 | |

17 | Max. feeding rubber strip thickness(mm) | 8 | |

18 | System pressure(MPa) | 21 | |

19 | Motor power of oil pump(KW) | 15x2 | |

20 | Oil tank capacity(L) | 400 | |

21 | Total power(KW) | 70 | |

22 | Machine dimensions(L×W×H mm) | 3680×2020×(2750~3250) | |

23 | Machine weight(KG) | 9500 | |

DETAILS

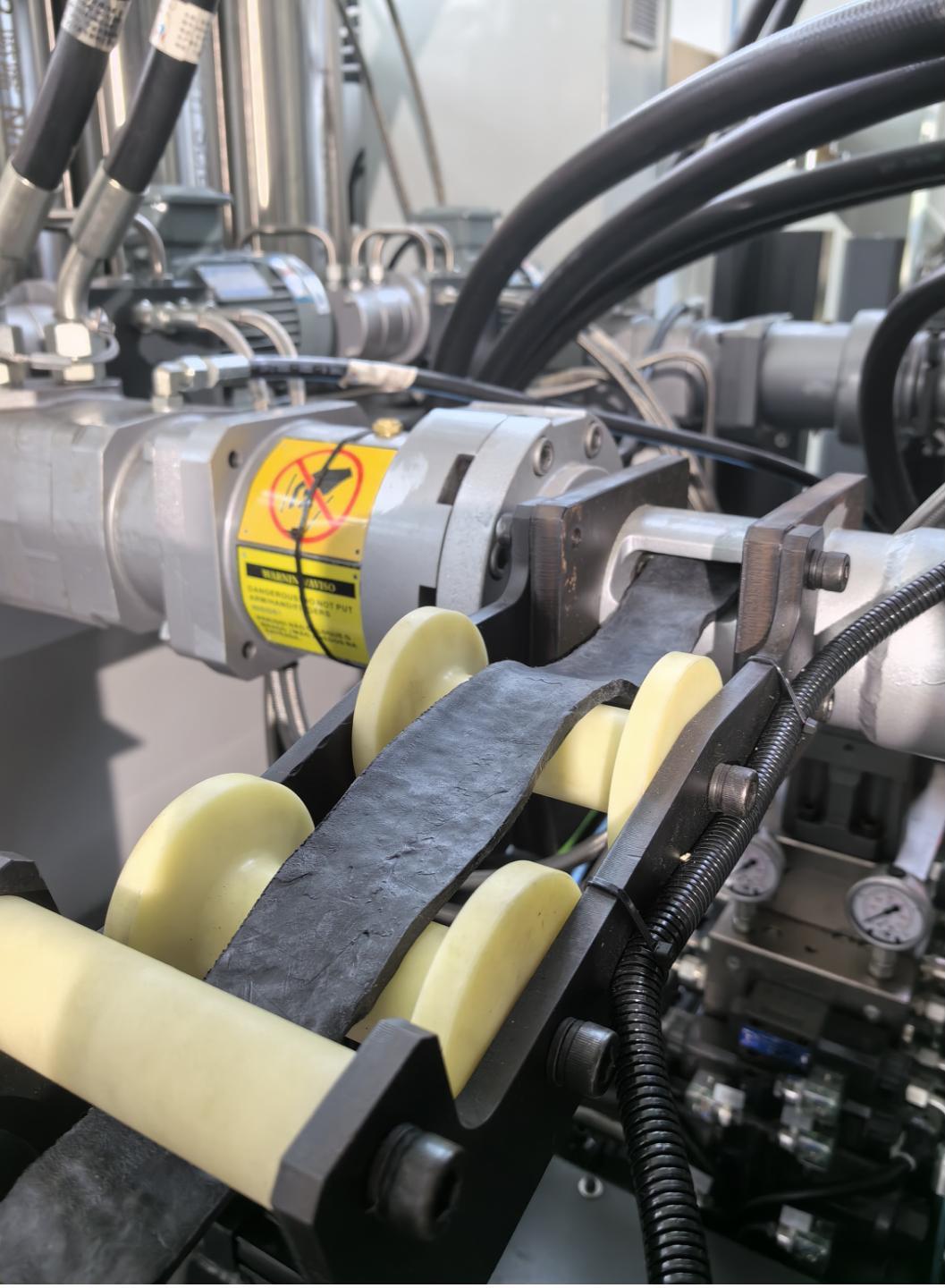

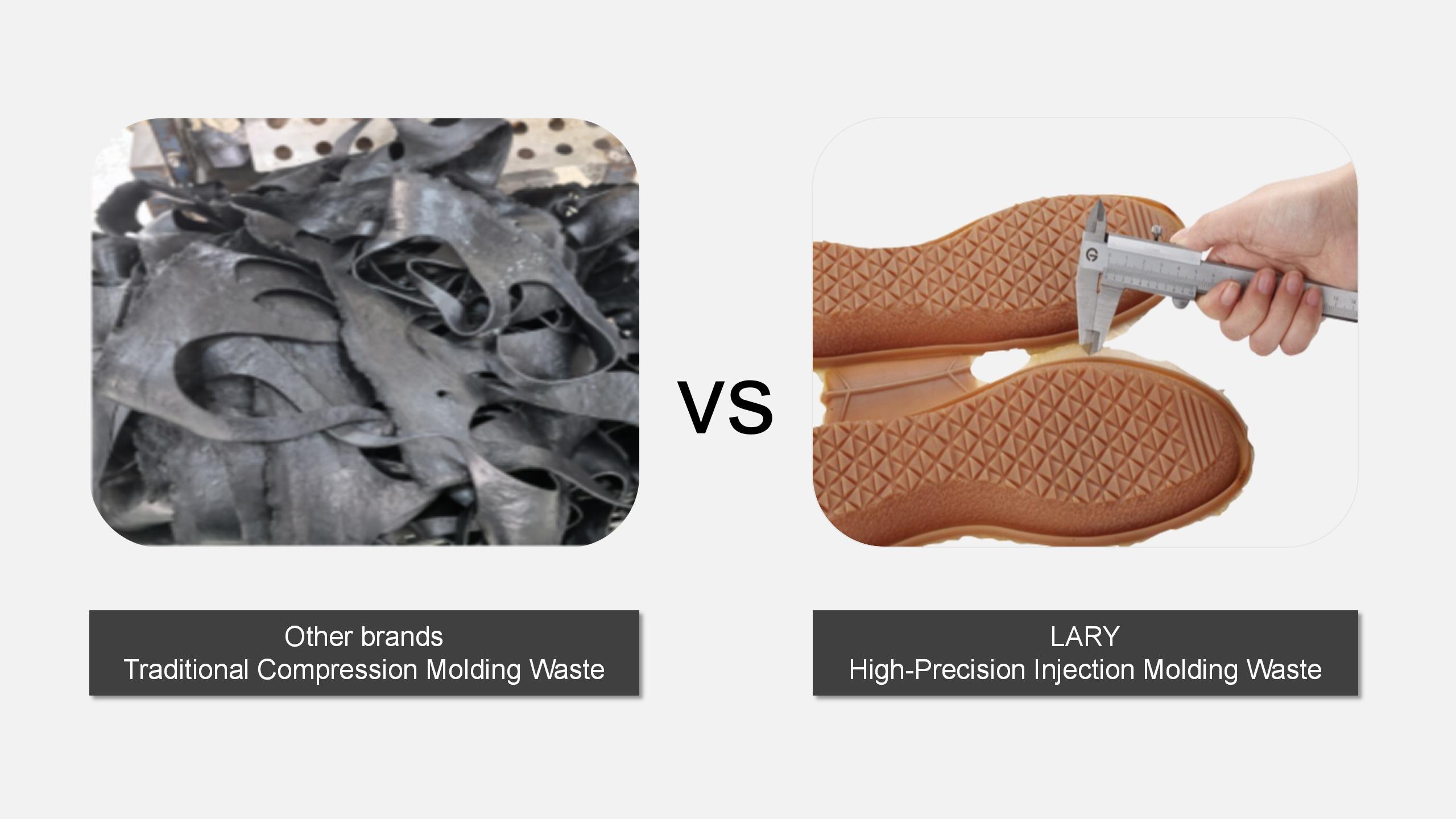

Material Savings & Process Optimization

Traditional compression molding requires pre-forming the rubber compound, generating significant edge trim waste and inefficiencies in recycling.

LARY' s rubber injection molding machine eliminates the need for pre-forming, reducing this type of waste. Additionally, its high-precision injection minimizes flash and material loss within the mold, further optimizing resource utilization.

Increased Production Capacity

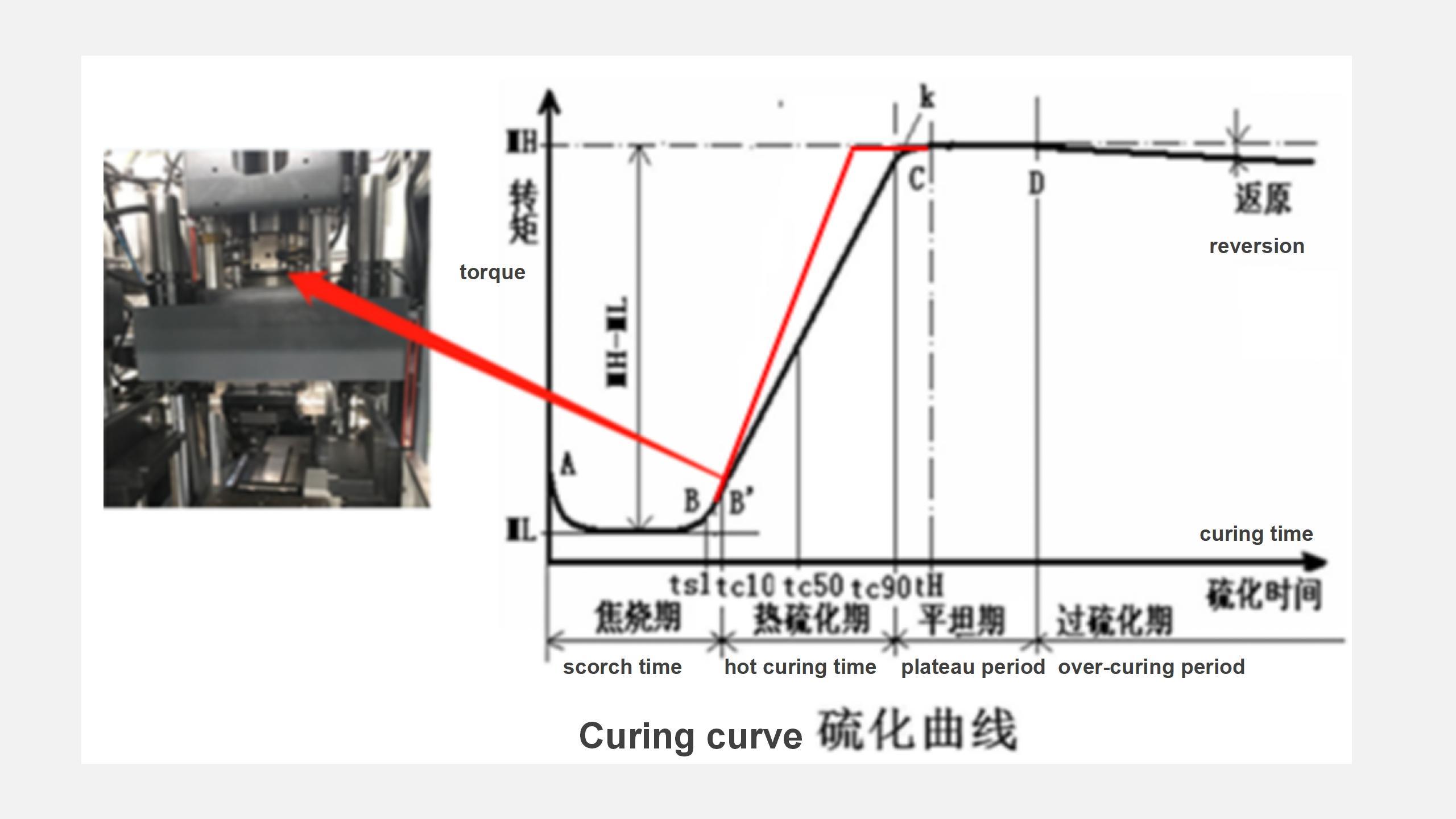

During the production of a single mold sole, the feeding system pre-measures and feeds the rubber for the next mold, preheating it by mixing and plasticizing it again in the screw.

Once in the barrel, the rubber is heated to 70–80°C for softening, reducing the vulcanization time in the mold by at least 40% and significantly boosting production efficiency.

Eliminating Color Bleeding in Multi-Color Soles

LARY' s advanced injection system, utilizing a middle plate production process, significantly reduces color bleeding and cross-contamination. With high and uniform injection pressure, along with secondary mixing inside the screw, the machine ensures optimal rubber blending while preserving its physical properties to the greatest extent.

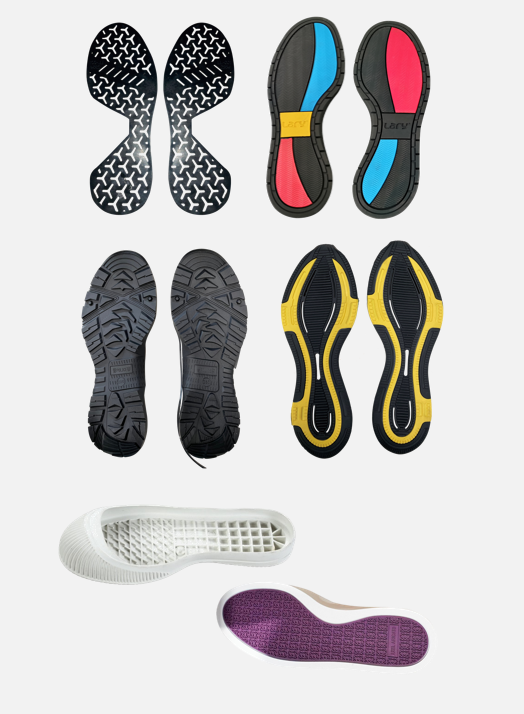

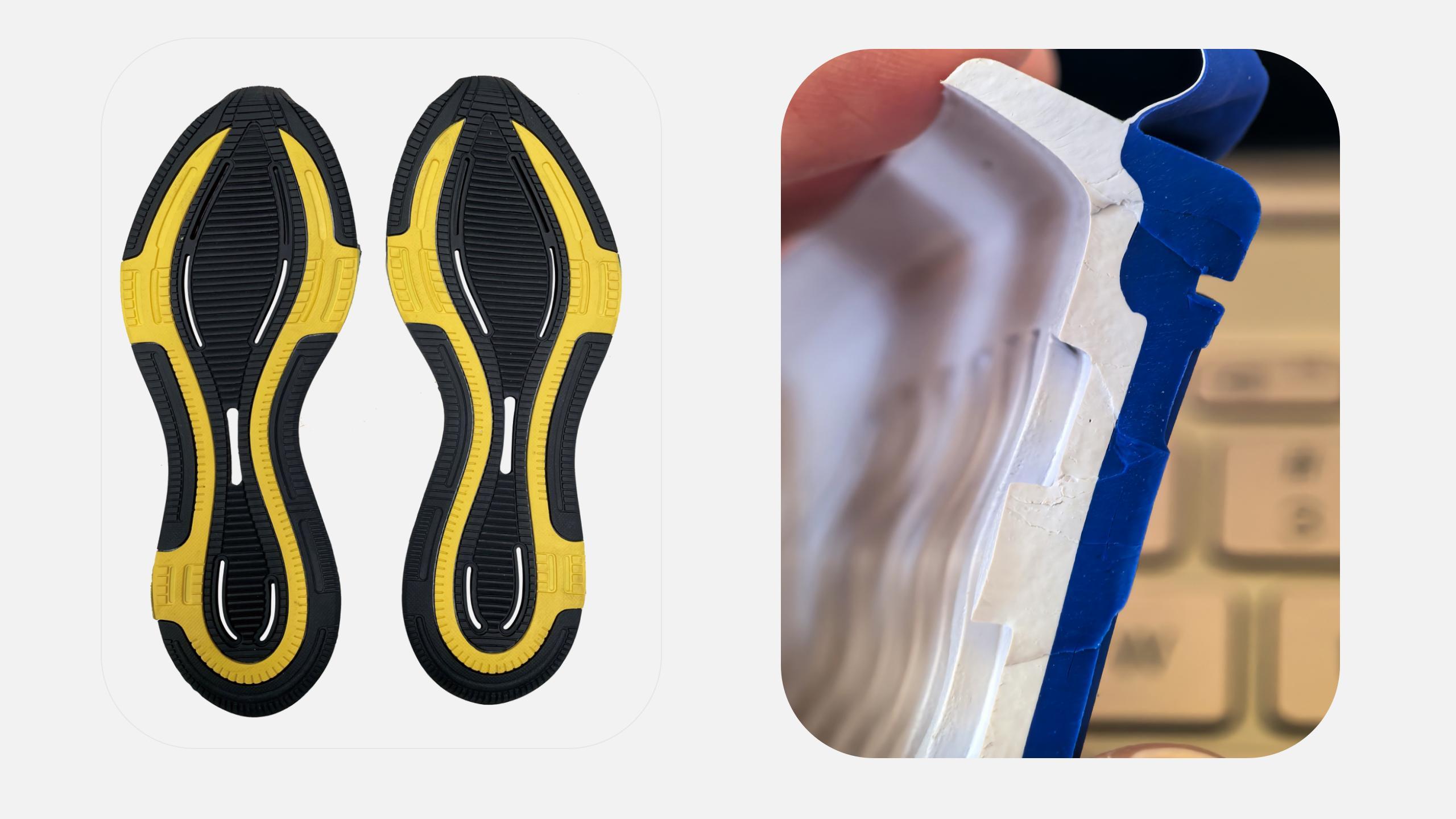

APPLICATIONS

Suitable for making various types of shoe soles !

- 1Sports shoe soles

- 2Sneaker shoe soles

- 3Safety shoe soles

- 4Special-purpose shoe soles

- 5Outdoor shoe soles

- 6heel shoe soles, etc...

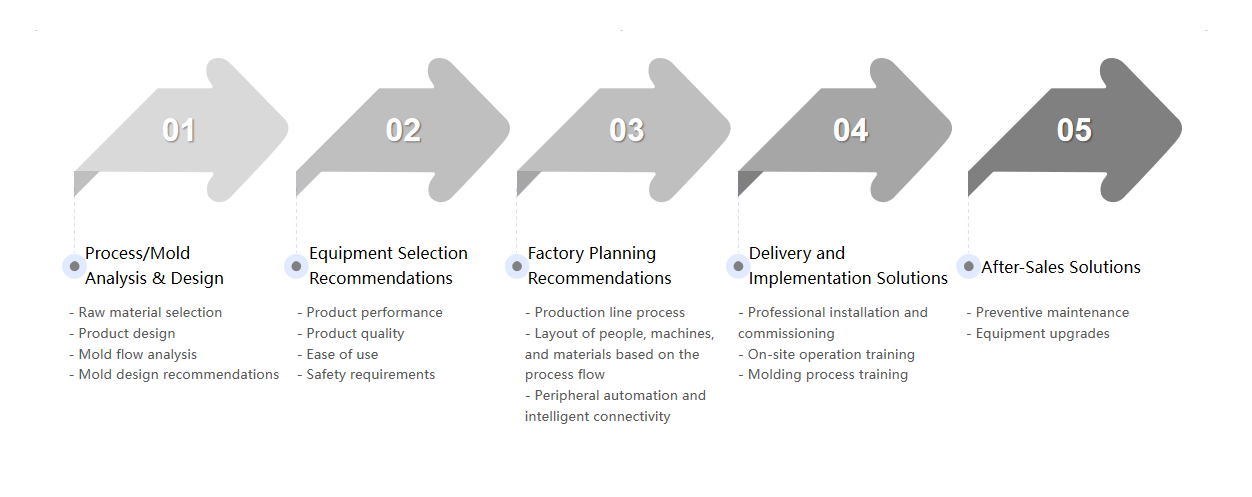

SERVICE PROCESS

Please send your message to us

- Tel

- *Title

- *Content

Contact Person

- Name:

- Amy Ren

- Tel:

0086-13958255267

0086-574-88033926

- Email:

- amy@larytec.com

- Skype:

- Skype:amyren600

- Address:

- No.9, JinGu Middle Road,Yinzhou District, Ningbo City, China

subscription

qr-code

E-mail:inlary@larytec.com

E-mail:inlary@larytec.com